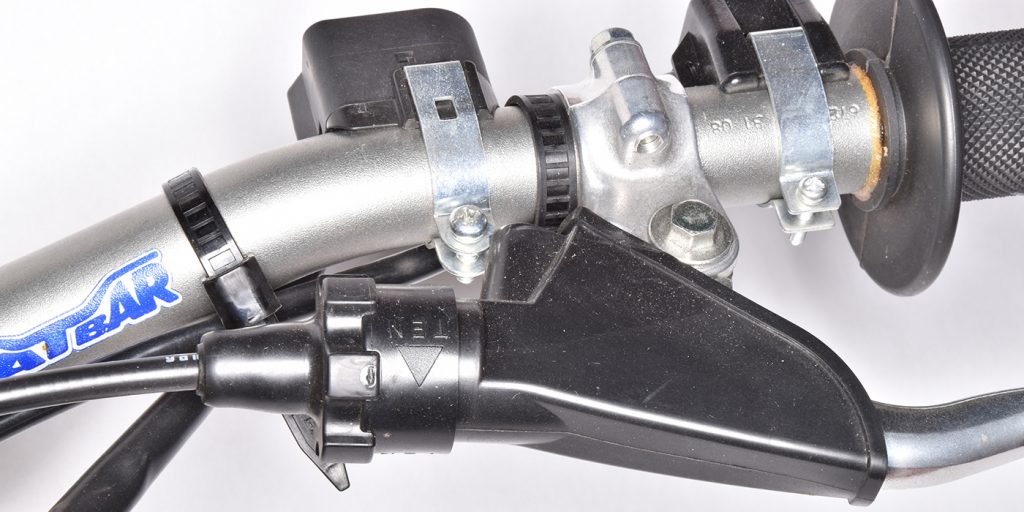

A motorcycle or ATV comes into the shop with complaints of a creeping or slipping clutch. Before jumping in and replacing the clutch plates, quickly check the clutch cable free play and any other clutch adjustment features on the particular model. Many new or nontechnical riders end up riding around with clutches far out of adjustment. Not only can this make for a poor performing clutch, but it can accelerate the wear of the clutch components.

If all of the adjustments are within specification, and the clutch is still failing to function correctly the clutch components need to be inspected. In most cases, the bike will require a new set of clutch plates, but there are other components that should be inspected while working with

the clutch.

Measure the length of the clutch springs to check for

fatigue, sometimes the springs will even be broken. Replace all of the clutch springs as a set if one is out of the

service limit or the lengths vary dramatically across the set.

Note the position and orientation of special components. A typical motorcycle wet clutch pack consists of steel discs and the same number plus one of friction discs. However, many times special clutch plates and/or judder springs may be included. These special plates may have a different inside diameter to fit over a judder spring and seat, or a different friction material, different tangs or special markings. Pay attention as the clutch pack is disassembled. Note the placement and orientation of any special clutch plates or

judder springs.

Look for signs of damage on the clutch plates. Check the steel plates for warp and discoloration, if the fiber plates don’t look bad, measure the thickness to be sure. The service manual will have specifications for inspection, but usually there is plain evidence of the need for new clutch plates. Whatever the case, plan on replacing all the plates as a set.

Check the clutch basket and hub for wear and damage. If the basket or hub become overly worn, the pack will not be able to expand and contract smoothly. Also, check the condition of the clutch lifter/pusher components and bearings.

Be sure to soak the new friction plates in oil prior to installation, however some newer clutch plate kits claim this is not necessary, so follow any specific instructions. Coat the steel plates with oil if they are dry or new.

A wet clutch is sensitive to the type of oil used. Use the correct motorcycle oil for the application and, if possible, find out what type of oil was used in the engine last. Install the clutch pack into place, alternating friction and steel plates. Make sure that all of the steel plates are installed with the same orientation.

Make sure special components are installed in the proper place. If the clutch has multiple clutch plate types or special components like judder spring, be sure to install them in the specified order and orientation so the clutch can function as it was intended. Don’t assume these additional parts always sit in the same spot in every clutch pack. Check the service manual since how these special components are installed varies

between models.

If applicable, adjust the clutch after installation, following any specific instructions provided by the manufacturer. Tighten the clutch spring bolts evenly and in a crisscross pattern until the correct torque spec is reached. The bolts and holes they thread into can be easily damaged by a heavy hand or powerful tool. Assemble the rest of the machine and follow any specific clutch adjustment procedures for that model.

If everything is correct, the last step is a nice test ride!