In the early days of motorcycling, brakes were applied by sticking your foot out to stop. Then in 1902 Steffey Motorcycles of Philadelphia employed a spoon brake on the front wheel. This system essentially pressed a steel plate against the tire to slow the bike down. It was not very efficient but it was better than wearing out your shoes.

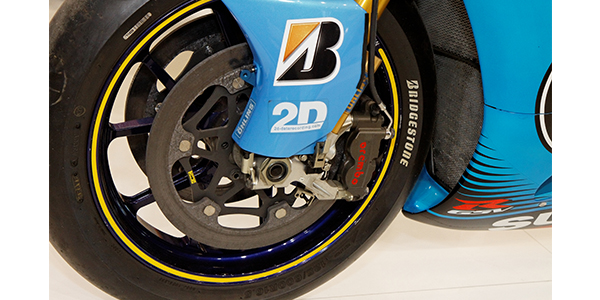

With some of today’s production motorcycles able to hit speeds of 200 mph (on a closed course, of course), stopping is as important as acceleration. The braking systems used on modern motorcycles are vastly superior to the bikes of the past, but one thing that remains the same is that most of the braking force is produced by the front brake. In fact, most motorcycles today use the front for 70 percent of the stopping power.

When it comes to upgrading brakes, however, motorcycles are as diverse as their owners. Cruisers with longer wheelbases may require more braking in the rear, whereas a sportbike with taut front suspension and a short wheelbase can withstand more front braking force. But one commonality is that most riders want to stop better, and dealers who are knowledgeable can help customers make the right upgrades for their situation.

It is always important to base an upsale decision on where the product will be used, according to SBS’ Chris Jensen. “A customer may insist on a full-on race product for his/her street bike that in reality isn’t made for street use,” he explains. “Instead, there are high performance street brake pads that will work much better in this particular situation.”

For actual track use, Jensen says it is important to determine the feel that a customer is looking for as this is very much personal preference. “Carbon-based brake pads generally have less initial bite than sintered pads but provide a very similar overall friction level, or stopping power.”

There are several ways to upgrade a brake system, but the best way to start is with pads and steel braided brake lines combined with a quality DOT 4 or higher brake fluid. “Most riders are surprised of how big an upgrade a set of brake pads can be, and the investment in replacing stock rubber brake lines with steel braided types is money well spent,” says Jensen.

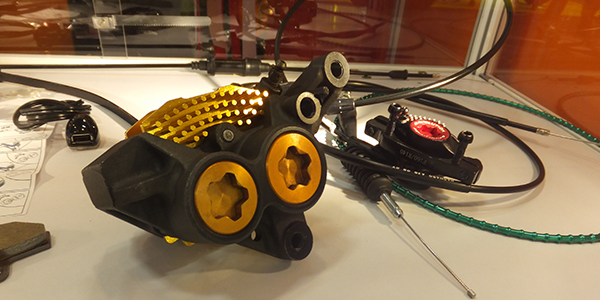

As a rider progresses in skill level and as lap times start falling, they can continue the upgrades with an aftermarket master cylinder and brake calipers in that order.

TAW’s Wayne Rodgers, the U.S. importer of Brembo, says that a motorcycle is like a small ecosystem and every time you change one part it will affect another one. “A brake system is only as good as the tire’s contact patch. You can only add so much brake before the limit is reached. These things are changing all of the time, depending on the suspension and wheels and how they work together. Brembo tries to keep on top of it in racing and then what they learn from racing, they use in the next two levels of high performance upgrades. The manufacturers are building bigger, faster bikes and they need the brakes to perform as well.”

Rodgers adds that the stock brakes on a new superbike are better than a MotoGP bike 15 years ago. “It gives you a lot of respect for those older riders.” He also points out that enthusiasts are very aware of what is out there on race machines and are willing to pay to get systems that are similar. “[Enthusiasts] are always demanding new things,” says Rodgers. “If we were silly enough to try and sell MotoGP carbon brakes people would pay $10,000 or more for them just to say they have them.”

Manufacturers like Brembo build a lot of sensitivity into their calipers, so friction material is very critical. “If the pistons retract too far from the pads, you’re going to have a massive handful of lever next time you go for the brake; it’s going to come back to the bar,” according to Rodgers. “But if you don’t pull off enough from the rotor, you’re going to get residual drag and sap energy from the bike on the straights and everywhere else. There’s a lot of precision in getting the pad to come away from the rotor very slightly. If you look at the MotoGP rider, he uses one finger for braking.”

Brake pad compound determines the feel that a rider will experience, so it is very important to match the compound to the rider’s expected usage and general expectations.

“A common mistake is selling brake pads made for street use to a racer or trackday rider,” says Jensen. “The heat generated on the race track, even at beginner pace, typically exceeds the recommended range of a street compound with reduced performance to follow. Just because brake pads are HH rated, doesn’t necessarily mean that they are meant for track use.”

Generally, there are two types of brake pad compounds; ceramic (organic) and sintered metal. Jensen says both can be found in street and racing versions, so it cannot be generalized that one is for street and one is for race use.

Street pads and race pads are made to perform at different temperature levels. While a street pad works very well at lower temperatures, a race compound is made to work better at higher operating temperatures. A street compound is also made to be very comfortable to use, with no noise or vibration, whereas using a race pad at low speed and with low brake pressure could possibly be a noisy affair.

While it may seem old fashioned, dealers can accelerate brake sales simply by leafing through their brake supplier’s catalog or website and seeing what’s new. Another tip to stopping customers in their track is to put a bike on the showroom floor equipped with the braided steel lines, new master cylinder, caliper and rotors… all rolled into the finance package. Sure beats the Fred Flintstone approach to braking!