Troubleshooting Electrical Problems

Troubleshooting Electrical Problems

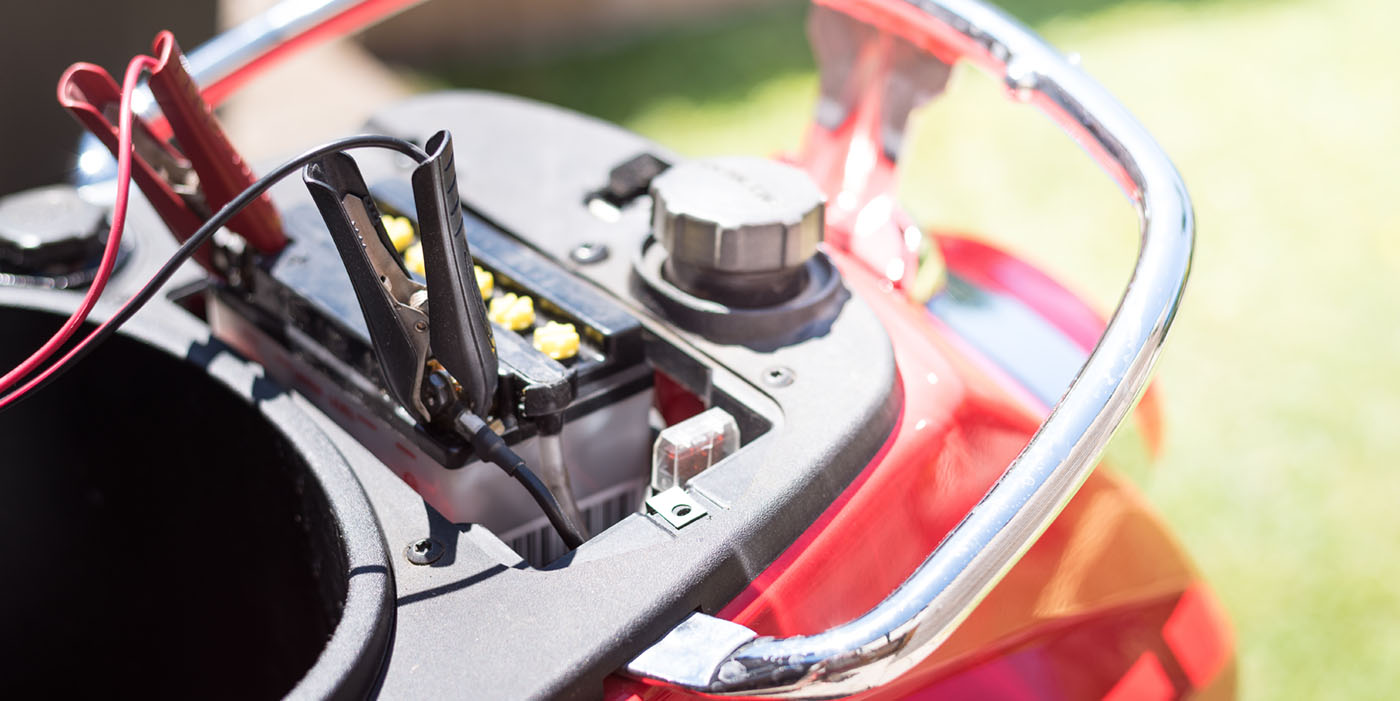

Part 1 of ignition system no spark troubleshooting focused on the general electrical problems that often result in no spark conditions. This month (Part 2), we go deeper into testing the specific components of the ignition system. Testing the components will require a multimeter for measuring voltage and ohms of resistance. Also, a peak voltage adapter (PVA) will be needed for the multimeter to read pulse voltage where the voltage increases and decreases in a short period of time.

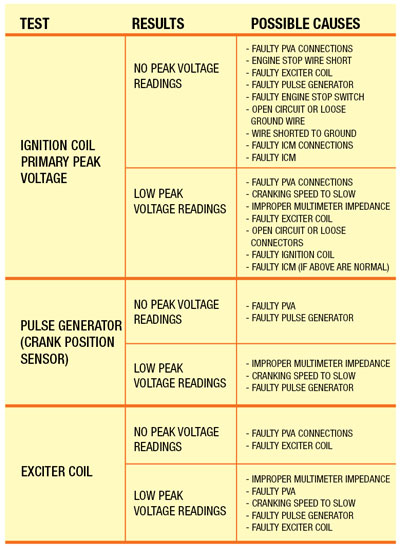

Place the ignition system in a condition similar to checking for spark when conducting peak voltage testing. There should be spark plugs installed in the cylinder head and known good plugs installed in the spark plug caps. The spark plugs in the caps should be grounded to the engine. All ignition circuit switches should be placed in run positions. The connector being tested for peak voltage may need to be plugged in during the test. Use the kick starter or electric starter to turn the engine over and measure the peak voltage with the PVA and multimeter. If the peak voltage is out of specification test it at other locations if possible. For example, test the crank position sensor peak voltage at the crank position sensor connector and at the ECM connector. The peak voltage should exceed the minimum specification given in the service manual.

Place the ignition system in a condition similar to checking for spark when conducting peak voltage testing. There should be spark plugs installed in the cylinder head and known good plugs installed in the spark plug caps. The spark plugs in the caps should be grounded to the engine. All ignition circuit switches should be placed in run positions. The connector being tested for peak voltage may need to be plugged in during the test. Use the kick starter or electric starter to turn the engine over and measure the peak voltage with the PVA and multimeter. If the peak voltage is out of specification test it at other locations if possible. For example, test the crank position sensor peak voltage at the crank position sensor connector and at the ECM connector. The peak voltage should exceed the minimum specification given in the service manual.

1. Inspect the ignition coil(s) as indicated by the service manual. This may include peak voltage testing and/or resistance testing.

2. Use resistance testing to inspect the ignition system components if peak voltage testing specifications are not available. Measure the primary resistance between the two terminals of the ignition primary coil.

3. Measure the primary resistance between the terminal and a ground if the coil only has one terminal.

4. Check the secondary coil resistance between the primary ignition coil terminal and the spark plug cap.

5. Check the secondary resistance between the two spark plug caps if the ignition coil has two spark plug wires.

6. Also check the resistance with the caps removed from the wires if specified. Replace the ignition coil, spark plug wire, or caps as necessary if the resistance is out of specification.

Inspect the crank position sensor, pickup coil, and/or exciter coil for resistance and peak voltage according to the service manual. If possible check this a multiple locations like at the coil connector and at the ECM connector. Not only do we need to know that the component is functioning correctly, but we need to know that the related wiring is intact. The crank position sensor and exciter coil often must be replaced with the stator as an assembly.

Inspect the ignition system related switches for correct continuity according to the service manual or wiring diagram. This usually includes the main (ignition) switch, engine stop switch and side stand switch. Other switches involved may be gear position/neutral, reverse override, tip-over, and other ignition based safety switches. Replace any faulty switches or switch-related wiring.

Inspect the ignition system related switches for correct continuity according to the service manual or wiring diagram. This usually includes the main (ignition) switch, engine stop switch and side stand switch. Other switches involved may be gear position/neutral, reverse override, tip-over, and other ignition based safety switches. Replace any faulty switches or switch-related wiring.

In rare cases there are resistance tests for the ignition control module (ICM) or engine control unit (ECU). Most of the time the only way to determine if an ICM/ECU is faulty is to rule out all other options. Unfortunately, many people want to jump ahead and reach this conclusion before fully inspecting the entire system. It is far more likely that a bad connector or wire is the cause of the problem than the black box. With that in mind, don’t even consider replacing an ICM/ECU unless you are 100% confident that all ignition system components, switches, wires, and connectors are in perfect working order.

Cyclepedia Press LLC authors powersports service manuals, a specification database and training modules to help technicians efficiently service ATVs, motorcycles, scooters and side-by-sides. Each month Cyclepedia examines real life shop scenarios with recommended tech tips for handling the problems encountered. For more information about Cyclepedia manuals and professional products, visit www.cyclepedia.com.