Driven clutch and belt System

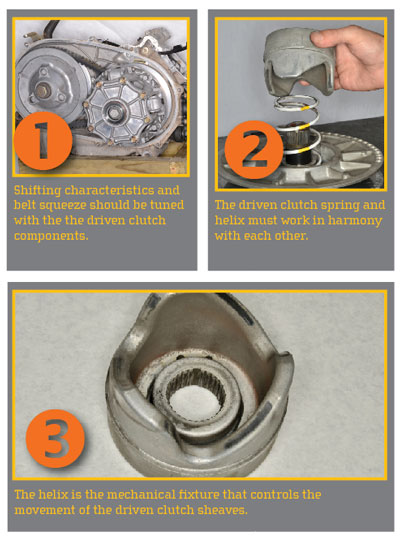

[dropcap]P[/dropcap]art one of CVT clutch tuning focused on the tunable aspects of the drive clutch. Part two will focus on the driven clutch and belt. While initial belt engagement and engine rpm adjustments should primarily be adjusted with the drive clutch, the shifting characteristics (especially downshifting) and belt squeeze should be tuned with the driven clutch components.

1. The driven clutch has a spring and helix shape that can be changed to alter performance. The driven clutch spring and helix must work in harmony with each other and with the tuning of the drive clutch for optimum total system performance.

1. The driven clutch has a spring and helix shape that can be changed to alter performance. The driven clutch spring and helix must work in harmony with each other and with the tuning of the drive clutch for optimum total system performance.

The driven clutch spring plays a critical role in belt squeeze and heat. Unlike the drive clutch that has weights, the driven spring is compressed by the belt moving in the sheaves. This spring will be rated with an initial compression and full compression spring rates like the drive clutch spring. The spring needs to be selected to deliver the right amount of squeeze at initial belt engagement through to maximum shift out.

The belt squeeze maybe too little or too much at a specific point in the shift range if the spring rates aren’t optimal. The initial spring rate of the driven clutch spring needs to be increased if there is too much belt slippage early on in the shift curve. The final compression spring rate needs to be increased if the belt begins to slip late in the shift curve.Insufficient belt squeeze will cause the belt to slip on the driven clutch. This slippage will cause the driven clutch and belt to get hot and should be avoided. Excessive heat can also be created by too much belt squeeze. Also, an overly stiff spring will cause accelerated component wear.

2. The driven clutch spring works in combination with the helix to control shift rate. The driven clutch spring must be stiff enough to prevent belt slippage, but not so stiff as to prevent upshifting. Generally, a stiffer spring will make for a faster downshift and slower upshift, and a softer spring with make for a faster upshift and slower downshift, but the helix’s resistance to shifting also comes into play.

3. The helix is the mechanical fixture that controls the movement of the driven clutch sheaves as rollers follow angles on the helix fixture. The helix can have a single angle (straight helix), multi-angle, or progressive shift between two angles.

A shallow angle helix (example: 38°) creates more belt squeeze, slower upshift and faster downshift. A steep angle helix (example 70°) will create less belt squeeze, quicker upshift,

and slower downshift.

A straight angle helix allows for fast upshifting and simplifies tuning. A multi-angle allows for multiple helix angles as the CVT shifts out and back. This changes the resistance to shifting and is used to create different loads at specific points in the shift curve. A progressive (or inverse progressive) helix use a curved cut on the helix so the helix angle changes gradually. It is important to mind the intermediate angles in the curve on a progressive helix as little time is spent at initial engagement and maximum shift. The aftermarket has many options for changing a helix, and custom made helix parts can be had at reasonable prices for popular models.

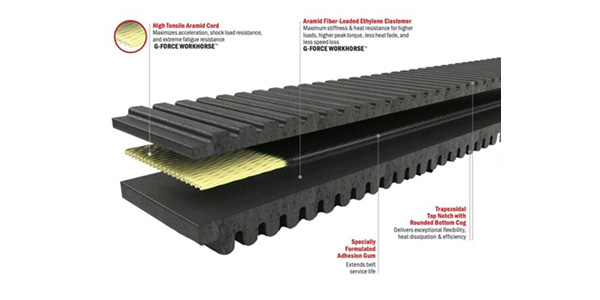

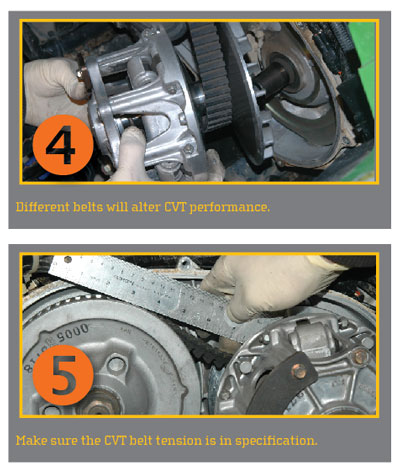

4. The belt shouldn’t be overlooked in CVT tuning. The CVT should be tuned with a specific belt in mind. Belts from different manufactures will vary in size and material even though they may claim to be equivalents. A thinner belt will create greater belt to sheave clearance. The clutches should be shimmed to fit a specific belt. Generally a softer belt will get better traction on the sheave faces, but wear faster than a harder belt.

4. The belt shouldn’t be overlooked in CVT tuning. The CVT should be tuned with a specific belt in mind. Belts from different manufactures will vary in size and material even though they may claim to be equivalents. A thinner belt will create greater belt to sheave clearance. The clutches should be shimmed to fit a specific belt. Generally a softer belt will get better traction on the sheave faces, but wear faster than a harder belt.

5. When tuning a CVT, remember to make sure the components are in good condition to start with. Also, mind clutch alignment, belt to sheave clearance and belt tension according to the OEM specifications. There isn’t a single tuning spec or bolt-on parts kit that will work perfectly in all conditions and all applications, but with a little time and tuning the CVT performance can be tailored to fit the operator’s needs.