The Korean Helmet Company Gives Us An Insider’s View of its Vietnam Plant

The Korean Helmet Company Gives Us An Insider’s View of its Vietnam Plant

[dropcap]S[/dropcap]ince we were in the neighborhood for the Taiwan International Motorcycle Industry Show last month, we figured we would extend our trip by stopping in to see a helmet factory nearyby and add frequent flyer miles in the process.

We were fortunate that someone took us up on our request. As one of the world’s top producers of helmets, HJC was gracious enough to host us at its manufacturing facility just outside of Hanoi, Vietnam on the last leg of our trip around the globe.

The factory came online just before the introduction of its flagship Rpha series that was launched in 2009. Later, the Rpha 10 was launched in Oct. 2010 at this facility with the help of none other than MotoGP Champion Jorge Lorenzo. With two other factories in Korea and China, HJC shifted most of its entry-level helmet production to its newest facility in Vietnam but still produces most of the premium models in its Korean factory. Today, HJC Vietnam employs about two-thirds of the company’s total work force, nearly 1,000 people.

The factory came online just before the introduction of its flagship Rpha series that was launched in 2009. Later, the Rpha 10 was launched in Oct. 2010 at this facility with the help of none other than MotoGP Champion Jorge Lorenzo. With two other factories in Korea and China, HJC shifted most of its entry-level helmet production to its newest facility in Vietnam but still produces most of the premium models in its Korean factory. Today, HJC Vietnam employs about two-thirds of the company’s total work force, nearly 1,000 people.

Even though socially it’s still under communist rule, Vietnam has a booming agribusiness (coffee production is second only to rice) and a rapidly growing industrial sector in a nation that most of us only know from war movies such as Platoon or one of our favorites, Good Morning Vietnam. Victory over America and France is one of the few holidays Vietnamese celebrate besides the lunar New Year. But the Vietnamese do not hate America – far from it, in fact.

According to recent Pew research, Vietnam has a very favorable view of the U.S. Most of the younger generation views capitalism as the way forward. About 15 years ago, the government began to relax laws that restricted trade and business in order to bring up its GDP. It worked!

Another big influence on Vietnam is South Korea. Many Korean companies have moved manufacturing here because it is more economically viable for distribution of raw materials and shipping as well as access to a young, inexpensive and skilled workforce. Samsung is one of the largest employers in Hanoi with a factory that has more than 40,000 workers producing smartphones not far from HJC’s factory.

HJC even makes some helmets for Samsung’s factory workers with the Samsung logo on the side. This helps identify workers riding into work in the morning and going home at night, but also gives them a little more protection than the cheap “dollar helmets” we saw being sold on the side of the road.

One of the things that Americans would find interesting is that when you pull into the parking lot at HJC Vina, there are almost no cars. There is a small covered garage area off to the left as you enter the factory grounds and that is where most of the employees park their scooters and motorcycles. Unlike U.S. companies, nearly all workers ride to work every day. The parking lot is mostly used for trucks and invited dignitaries who come to visit (like us!). By contrast, Babcox/MPN uses 10 times the space for about one tenth of the employees. Think how much easier it would be to find parking if we all rode to work!

One of the things that Americans would find interesting is that when you pull into the parking lot at HJC Vina, there are almost no cars. There is a small covered garage area off to the left as you enter the factory grounds and that is where most of the employees park their scooters and motorcycles. Unlike U.S. companies, nearly all workers ride to work every day. The parking lot is mostly used for trucks and invited dignitaries who come to visit (like us!). By contrast, Babcox/MPN uses 10 times the space for about one tenth of the employees. Think how much easier it would be to find parking if we all rode to work!

Asian Market

HJC Vina’s domestic market for helmets is saturated with low-end models that it doesn’t make. These helmets are little more than baseball helmets and offer very little in the way of protection. However, HJC does make some mid-level helmets for the local domestic market, according to Lee Suk Woo, the plant’s general manager, who graciously gave us a tour of the plant. These would be some of the polycarbonate full-face helmets we saw coming off the line and a few private label models as well.

Although HJC mostly makes helmets for the export market at the HJC Vina facility, some production does reach the locals. Lee told us that of the helmets manufactured in Vietnam, about 60 percent are for North America and Europe. Another 25 percent are for other Asian markets and the rest are domestic shipments.

Coincidentally, we happened to be visiting during a big meeting of HJC’s Asian distributors, so we talked to them about their markets. The people we spoke to said they carried a number of brands we’ve never heard of. However, HJC has done well in its markets and has created a strong global presence.

North America and Europe

HJC has been in the U.S. since 1986, believe it or not. By 1997, HJC had become a top seller, mainly because dealers found the brand offered great value for their customers and HJC had good customer service, complete with a U.S. headquarters. While HJC always sold well for a value brand, it couldn’t make much of an impact (pardon the pun) at the premium level. It wasn’t until 2009 when HJC introduced its first premium helmet with a heavy MotoGP influence – the Rpha 10. HJC hasn’t looked back since!

Looking forward, HJC Corp. President S.J. Hong says that they are going to focus more on premium helmet markets in North America and Europe. He says this is where the biggest growth will come from in the years to come.

Lee s ays that HJC Vietnam produces several models at a time on typical production day. Some of the helmets won’t be branded with HJC logos due to private label contracts for other companies, however, he says they produce the majority of the mid-level and entry-level helmets for the company. Lee also says that they do all of this with only one shift per day. As we walked through the different production areas, he showed us files upon files of orders for all of the different models they produce on the multiple lines they run and, we must admit, it was an impressive volume of lids.

ays that HJC Vietnam produces several models at a time on typical production day. Some of the helmets won’t be branded with HJC logos due to private label contracts for other companies, however, he says they produce the majority of the mid-level and entry-level helmets for the company. Lee also says that they do all of this with only one shift per day. As we walked through the different production areas, he showed us files upon files of orders for all of the different models they produce on the multiple lines they run and, we must admit, it was an impressive volume of lids.

The first building we went into had a giant boiler and piles and piles of wood pellets to make the necessary steam for the production of the Expanded Polystyrene (EPS) which is essentially the same material that keeps your takeout dinner warm, but it also works great at absorbing an impact. The raw materials are loaded into the hopper and then heated to a specific temperature that puffs up the EPS to a specific size. Lee said that the final product is somewhat like a puffed rice (which is over-simplified for illustrative purposes). You have to get the temperature just right or it will not make the right sized pellet. All of the pellets are then processed through a machine for quality control and then fed into a huge mold making machine.

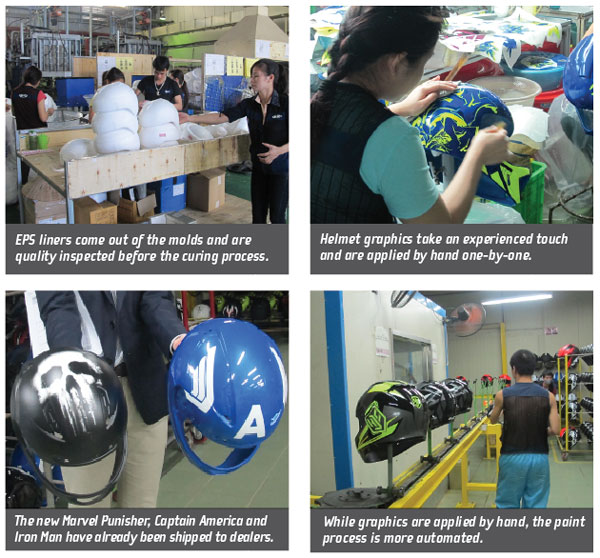

Lee says that all of the molds are designed and built back in Korea for each model and shell size. The puffed rice-looking EPS pellets go into the mold and are heated up again to a specific temperature with lots of steam and noise in the process. About 10-15 seconds later a clam shell lid pops out of the press. This is when the helmet starts to become recognizable. Lee says they make several different styles and shapes of liners, depending on the application. We saw at least three different liners being made that day. Some had channels in the top for cooling vents and to allow the right amount of impact absorption.

After the liners are made and inspected for quality by looking for areas that did not fill in properly with the material, they are set up in a heated room to cure. Even in the spring, Vietnam is hot, but this room was heated to a balmy 40 degrees C – about 104 degrees F! No need to stay in that room for long, but after a few hours of cure time the mold is properly set to give the liner maximum absorption. Remember, all helmets are designed for one time use, meaning if it is dropped from any significant height or is involved in an accident where it is smacked, it’s no longer able to absorb an impact the same as it did before. Think of Styrofoam that you press with your thumb. Does the indent ever rebound? Not exactly. Therefore, manufacturers recommend that any helmet involved an impact should be retired.

After the liners are made and inspected for quality by looking for areas that did not fill in properly with the material, they are set up in a heated room to cure. Even in the spring, Vietnam is hot, but this room was heated to a balmy 40 degrees C – about 104 degrees F! No need to stay in that room for long, but after a few hours of cure time the mold is properly set to give the liner maximum absorption. Remember, all helmets are designed for one time use, meaning if it is dropped from any significant height or is involved in an accident where it is smacked, it’s no longer able to absorb an impact the same as it did before. Think of Styrofoam that you press with your thumb. Does the indent ever rebound? Not exactly. Therefore, manufacturers recommend that any helmet involved an impact should be retired.

The Shell

Most of the areas we were not allowed to shoot photos in were the composite shell manufacturing areas. We did walk through the area and saw workers hand lay the fiberglass and Kevlar material into a mold that, once the resin was poured, would heat and disperse it evenly. Helmets were then taken to an area to be trimmed around the edges. We did shoot photos in the polycarbonate shell production areas. These helmets are produced quickly and with less need for a hands-on approach than the composite helmets. After everything is trimmed, workers hand sand each shell. It’s a time consuming process, even with helmets that are more mass produced.

Marvel Series

Just in time for summer, HJC has released a series of Marvel superhero-themed helmets that are just now being shipped to dealers. We saw some of the first Captain America CL-17s and Punisher CL-17s manufactured during our tour. The Iron Man IS-17 is the third one in the series, but it was not on the production line at the time of our visit. It is yet another example of the foresight that HJC has as these characters are extremely popular, not just in the U.S., but all over the world. HJC says there’s more of this coming but couldn’t say anything on the record just yet. Trust us, though, it’ll be as big as the Marvel series.

Rpha Premium Series

In 2009, HJC introduced its first true premium helmet with the help of international racers Jorge Lorenzo and American Ben Spies giving feedback. It was maybe a watershed moment for HJC, which had until this point been a mid- to economy level manufacturer for what is essentially the bulk of the market. But in the helmet industry, you have to have a premium-level helmet to be considered a top brand. HJC has now introduced its latest and greatest – the Rpha 11 Pro.

The Rpha 11 was launched in Europe in November of last year as an ECE-only model and has received great reviews so far, but as of press time, the North American version (Rpha 11 Pro) is yet to be released. We received the very first one for the U.S. market, which is DOT/ECE 22-05 certified and is also feather light at a little more than 1,400 grams. Some safety experts believe that Snell standards are too much for motorcycles. But it’s really a rider preference as to which certifications are best for their type of riding. ECE certification helmets are approved by nearly every racing organization and is used in more than 50 countries. The Rpha 11 Pro is in line with this way of thinking. We think it reflects the way more manufacturers will go in the future of helmet design.

The Rpha 11 was launched in Europe in November of last year as an ECE-only model and has received great reviews so far, but as of press time, the North American version (Rpha 11 Pro) is yet to be released. We received the very first one for the U.S. market, which is DOT/ECE 22-05 certified and is also feather light at a little more than 1,400 grams. Some safety experts believe that Snell standards are too much for motorcycles. But it’s really a rider preference as to which certifications are best for their type of riding. ECE certification helmets are approved by nearly every racing organization and is used in more than 50 countries. The Rpha 11 Pro is in line with this way of thinking. We think it reflects the way more manufacturers will go in the future of helmet design.

Lastly, HJC will be the first helmet manufacturer to be a headline sponsor of a MotoGP event later this year. Be sure to catch the 2016 HJC Helmets Grand Prix of the Czech Republic from Aug. 19-21.